SUSTAINABILITY

From sourcing responsibly to reducing our carbon footprint and taking

care of our communities – we are proud that our practices are in

alignment with United Nations Sustainable Development Goals.

PEOPLE

SOCIAL DEVELOPMENT

PLANET

ENVIRONMENTAL PROTECTION

PROSPERITY

ECONOMIC GROWTH

Sustainability is a key pillar of our mission, just as it

is for our parent company. We are committed to

protecting our planet, the quality of life of its

people, and to continuously improve the way we do

business, thereby aligning our activities to lead to a

better and more responsible tomorrow.

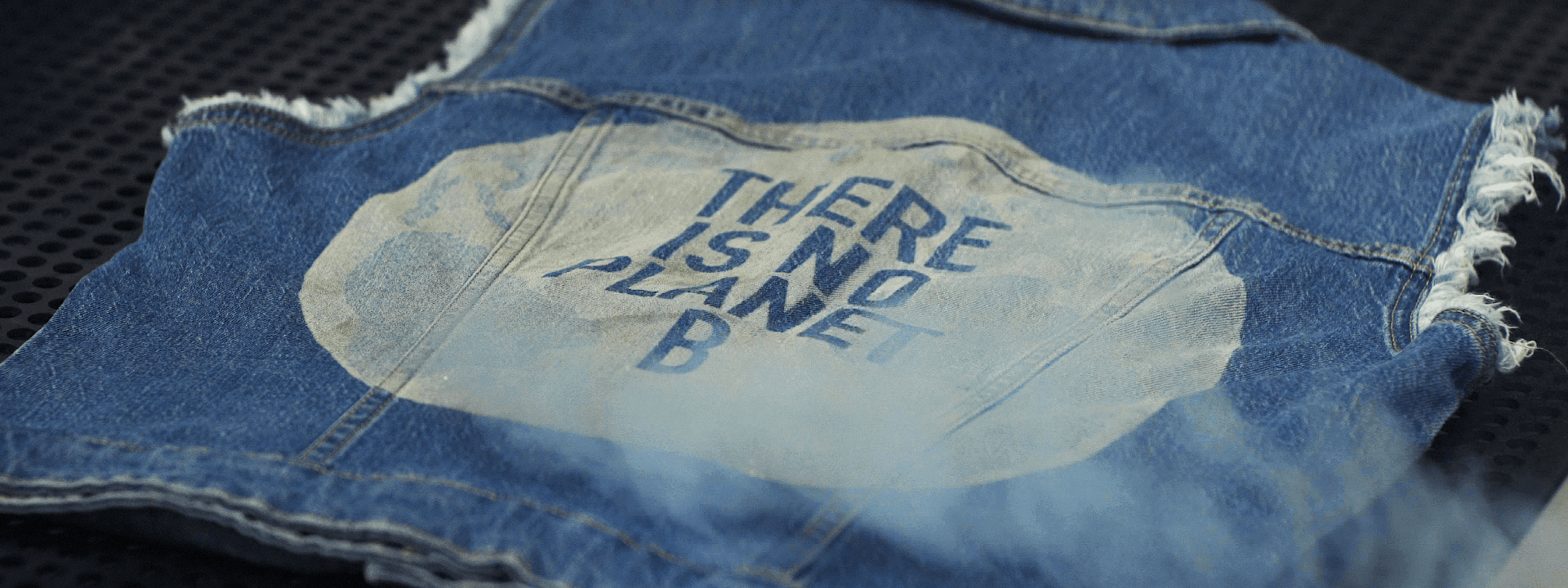

While ensuring we utilise the most eco-friendly

manufacturing processes, our commitment to

sustainability in an era of environmental crisis

has wider implications. We understand that to

be truly responsible we must strive towards a

circular economy and push forward conscious

consumption at all levels.

Our dedicated Corporate Sustainability Cell

evaluates our environmental initiatives, setting

ever more ambitious targets, and tracking our

impact on our community of workers, partners,

and the ecosystem.

We Save What Matters

total

ENERGY SAVING OF

665,870 KWH

total

C02 reduction OF

1,000 Tons

total

water saving OF

218,400 m3

EQUIVALENT TO

DAILY

ENERGY USE OF

19,818 HOMES

16,535

tree seedlings

grown for 10 years

DAILY WATER

consumption OF

191,579 Households

GREEN PROCESSES

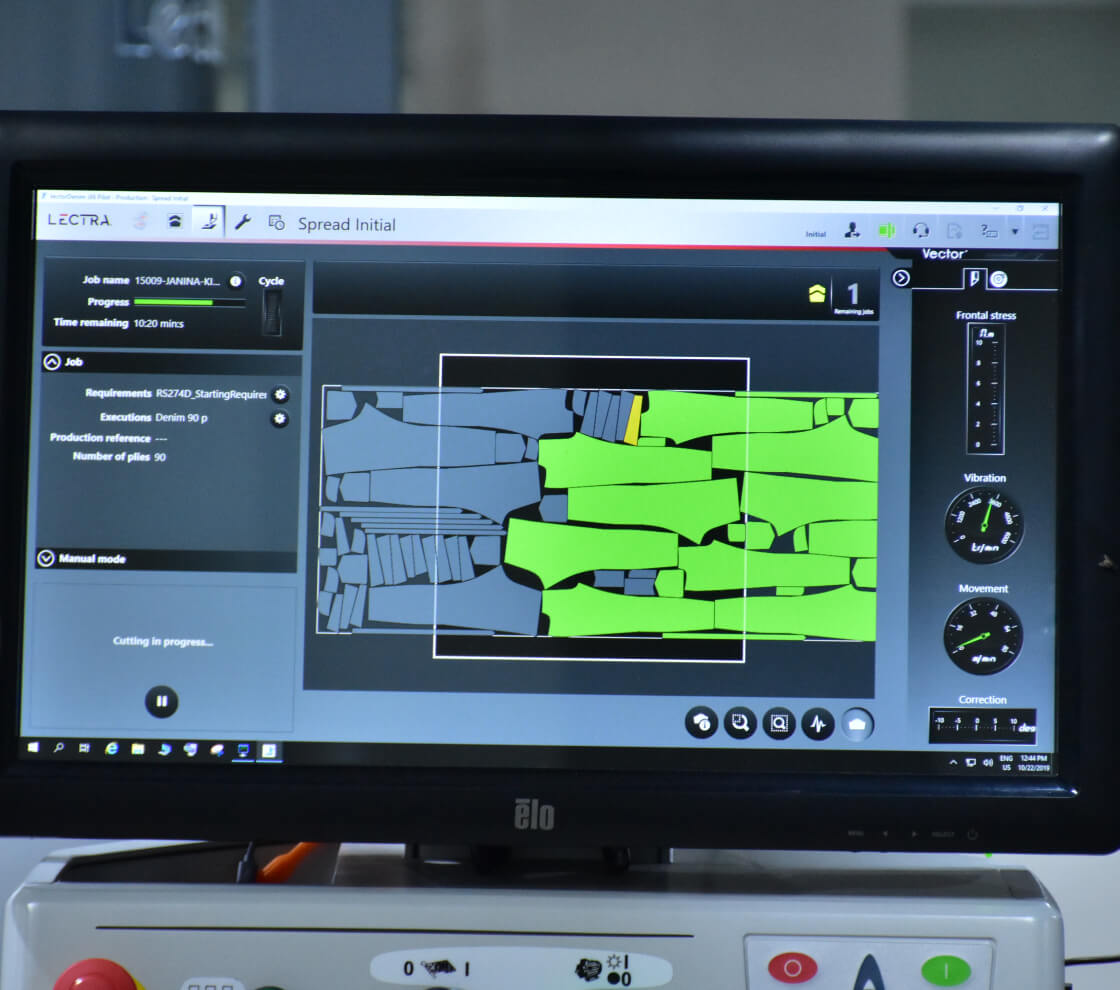

Our technologically advanced and highly automated LEED Platinum Certified facility incorporates the safest and most resource efficient technologies.

FOCUSED ON MINIMISING

LABOUR

WATER

ENERGY

MATERIAL

All cutting and sewing at our facility is automated, as are our laundry, high speed laser machines, ozone bleaching machines, and the finishing process. These eco-friendly technologies ensure a significant reduction in dry processes and chemical consumption.

Our laundry carries automatic chemical dispensing capability which allows us to measure chemicals

to the smallest unit ensuring consistency and standardisation. This enhances the accuracy and

improves transparency into the environmental impact measurements (EIM) for our products.

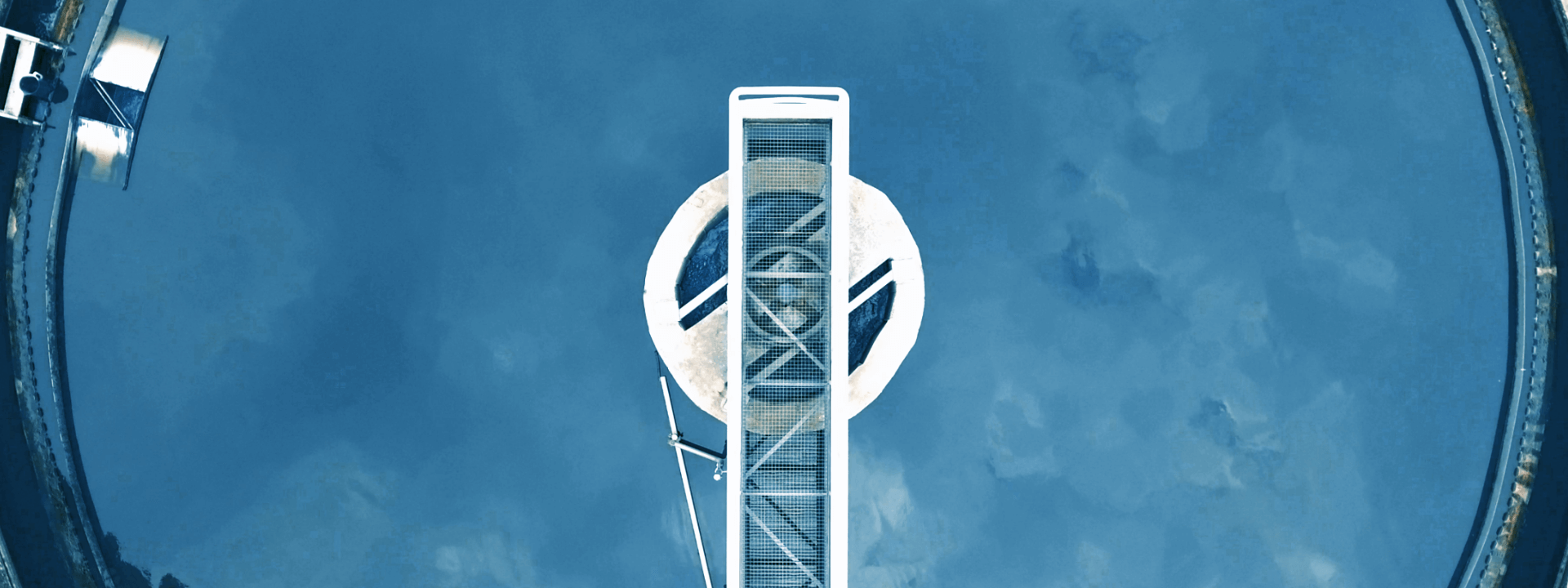

WATER CONSERVATION

We are keenly conscious of the inefficiencies of denim manufacturing, particularly when it comes to excessive water consumption. Being fully aware of impending global water crises, we have worked with global consultants, machinery developers, and fabric technologists to ensure our garments require not more than 30% of the water used in traditional denim apparel manufacturing. We are actively working towards achieving an even lower average of 10% water consumption.

We practice ecological and safe bleaching with ozone through

a zero discharge process.

Our entire laundry operates with water reuse technology, and utilizes UP and Core technologies, further saving water with a reduced liquor ratio.

ECO MATERIALS

Continuously experimenting with innovative fibres combined

with refined processes to lower wastage and usage of

chemicals, water, and energy.

Organic Cotton

Bamboo

Hemp

Recycled Polyester

With an already established prowess in multiple categories of the textile industry and a global reach in

material sourcing, we create bespoke fabric on demand with our local and international fabric partners.

RENEWABLE ENERGY

Investment in renewable energy and targeted energy consumption remain a priority for us. In 2019 we

reduced our annual carbon emissions by 15,000 tons and are further committed to enhancing our solar

capacity to 6 MW.

While we move towards renewable energy resources, our investments in responsible design and

manufacturing are already beginning to pay dividends in energy savings. Our energy efficient laundry

with short cycle times, and infrared heat recovery dryers save up to 20% energy. Our purpose-built facility

incorporates skylights, lighting 30% of the floor area, which reduce 56% of our carbon emissions

attributable to lighting.

WASTE MANAGEMENT

Interloop Limited recycles 90% of solid waste responsibly, pushing us closer to our goal of a circular economy.

Coal ash is one such waste product, which we upcycle into bricks. Our brick plant has a capacity to produce 7,000

bricks per day, requires zero fossil fuels and instead uses sunlight for curing. These very same 1 million bricks

have been used in the construction of our Denim Plant amongst other buildings at Interloop.

Our wastewater treatment and emission system treats 100% of Interloop Denim’s wastewater. To further our

sustainability vision, we plan to implement water recycling technology in the near future.

COMMUNITY

At Interloop, our people are truly our greatest asset and at the heart of everything we do.

Our culture of challenging and nurturing employees has

attracted talent from over 15 different nationalities.

Interloop is an equal opportunity employer

committed to promoting equality, diversity

and fair treatment. This begins with

recruitment, as we are focused on working

towards a 1:1 female to male worker ratio.

We have day care centres at all our facilities for working mothers, providing a healthy and safe

environment for their young children. Our Reconnect program helps mothers “Reconnect” with

Interloop after they’ve taken a career break.

We empower our people

holistically through awards programs, trainings

and prioritising their wellbeing with

comprehensive health benefits, providing

structured mentorship, running a range of

sports programs, and by celebrating their

diversity through numerous cultural and

religious programs.

GREENHOUSE GAS EMISSIONS

Interloop has a Waste Heat Recovery system which harnesses free steam. Bi-Generation system technology along with electricity produces around 20% of the total steam with significant reduction in greenhouse gas emissions. Our Waste Heat Recovery System reduced 5,530 tons of CO2 emissions in 2019 alone.