Green Processes

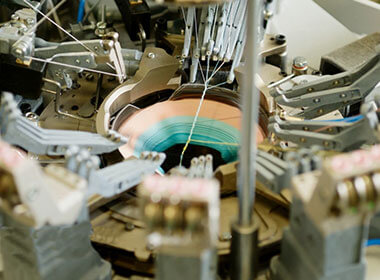

Challenging traditional approaches to denim manufacturing, our purpose-built facility incorporates the safest and most energy and resource efficient technologies to minimise our impact on the planet and its people.

Committed to our vision of producing denim apparel in a responsible and environmentally conscious way, we continue to leverage nearly 3 decades of manufacturing success to conceptualise, design and craft products that makes us proud every single day.

While using eco-friendly manufacturing processes is central to the way we do business, our commitment to sustainability in an era of environmental crisis has wider implications. To be truly responsible we must strive towards a circular economy and push forward conscious consumption at all levels.

Challenging traditional approaches to denim manufacturing, our purpose-built facility incorporates the safest and most energy and resource efficient technologies to minimise our impact on the planet and its people.

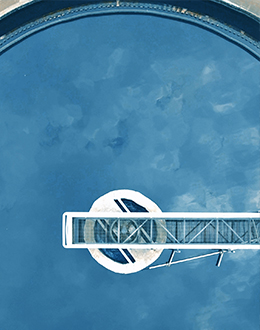

We continuously collaborate with global consultants, machinery developers, and fabric technologists to ensure that our products require not more than 30% the water consumed in traditional denim manufacturing.

Using innovative fibers and sustainable materials to reduce our carbon footprint.

Investment in renewable energy and targeted energy consumption remain a priority for us.

The water treatment plant treats 100% of Interloop Denim’s waste water.

Our culture of challenging, empowering, and nurturing employees has attracted talent from over 15 different countries.

Interloop takes immense pride in having launched various in-house skills enhancement programs, partnering with charities and other nonprofit organisations to support our local communities through turning challenges of a developing world into opportunities.

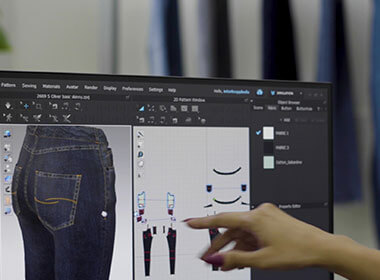

Some of our most exciting work happens within our Design Studio in tandem with our Research & Innovation and Product Development units dedicated to responsible design through innovation.

Along with laser technologies, we have been experimenting with faux stones and ozone to achieve greener garment finishes.

This entire process is supported by CLO, a 3d fashion design software for true-to life garment visualisation, and virtual fitting.

We have product technologists and wash technicians onboard to provide expert guidance regarding garment finishing and advanced washes.

With our strict parameters of efficiency, creative talents, and technical acumen we are intent on establishing a new normal of sustainable fashion that is accessible and timeless.

Interloop is proud to be recognised globally for its ethical and sustainable business practices.

Interloop Denim aims to become an agent of positive change, embracing ethical and sustainable business practices along each step of its value chain.